Description

Redefining the Benchmark for Spot Welding Quality: The All-in-One Electrode Cap Inspection Unit, Leading a New Era of Intelligent Process Control

In precision spot welding processes, the electrode cap serves as the core conduit for energy transmission. Its condition directly determines the stability of welding quality and the efficiency of production cost control. However, the industry commonly faces two severe challenges:

-

Difficulty in Detecting Quality Risks: Centrality deviation of the electrode cap and oxide residue on the end facecause uneven nugget formation, leading to hidden defects such as false welding and weak welding. Traditional manual inspection struggles to detect these in real time, creating significant quality risks.

-

Cost Control Relies on Guesswork: Under continuous, high-intensity welding conditions, there’s a risk of the electrode cap being milled through, causing coolant leakage. This not only leads to unplanned production line downtime but also, due to the inability to accurately predict lifespan, results in overly conservative preventive replacement cycles, generating 15%-30% redundant consumable costs.

These systemic risks have become critical bottlenecks restricting companies from improving welding yield rates and achieving lean production.

The Solution: Intelligent Integration Innovation, Defining a New Standard for Electrode Cap Lifecycle Management

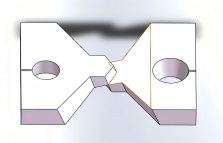

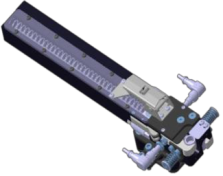

Addressing these pain points, we proudly introduce the All-in-One Electrode Cap Inspection Unit—a revolutionary intelligent quality control device specifically designed for spot welding processes. It deeply integrates high-precision industrial vision technology with powerful edge computing capabilities, combining image acquisition, data analysis, and localized storage functions into a single unit. This enables automated full lifecycle management of welding gun electrode caps, from “commissioning” to “decommissioning”.

Core Technology Principle: Empowering “Smart Manufacturing” with “Vision”

Based on advanced vision imaging principles, the All-in-One Electrode Cap Inspection Unit captures high-definition images of the end face in real-time during the electrode cap dressing process. Instant analysis is performed through its built-in AI algorithm model:

-

Precise Measurement: Accurately calculates the electrode cap’s feature length, axial angle, and the morphology of the end face after dressing.

-

Intelligent Judgment: Determines in real-time whether the dressing quality is qualified (OK/NG) by comparing against standard process parameters.

-

Seamless Feedback: Immediately feeds the detection results and data back to the robot or production line control system, guiding the next action and forming a perfect automated closed loop.

Core Value for Customers

1. Superior Quality, Guaranteed at the Source

-

Prevents welding with electrode caps that have centrality deviations, end face oxidation, or uneven wear, eliminating hidden defects like false welding and weak welding at the source, significantly enhancing product consistency and reliability.

2. Cost Reduction & Efficiency Improvement, Powered by Data

-

Reduce Consumable Costs: Precisely assesses the condition of the electrode cap after each dressing, establishing replacement strategies based on actual wear conditions, avoiding the waste of “replacing before it’s used up,” and directly minimizing redundant electrode cap costs.

-

Improve Production Efficiency: Enables 24/7 unmanned automatic detection, replacing inefficient and subjective manual checks, freeing up labor. Effectively provides early warning against the risk of cap mill-through, preventing unplanned downtime caused by coolant leaks, and ensuring continuous and stable production line operation.

3. Digital Decision-Making, Transparent Processes

-

All inspection data is stored locally with encryption, forming a complete, traceable quality record. This can be used not only for real-time monitoring but also provides powerful data insights and decision support for process optimization and predictive equipment maintenance, driving continuous improvement in welding processes.

Why Choose Our All-in-One Electrode Cap Inspection Unit?

-

Highly Integrated, Easy Deployment: The all-in-one design eliminates complex assembly and allows for seamless integration with mainstream robot brands and dressers for quick deployment, plug-and-play operation.

-

Intelligent Algorithms, Accurate & Reliable: Features built-in AI models trained on massive datasets, with strong anti-interference capabilities, ensuring high detection accuracy and stability even in complex working conditions.

-

Edge Computing, Real-Time Response: Data is processed and analyzed locally in real-time, offering fast response without relying on cloud networks, ensuring production data security and maintaining production line rhythm.

Move away from the traditional model reliant on experience and guesswork. Embrace the future of manufacturing driven by data and intelligent decision-making.

Contact us today to learn how the All-in-One Electrode Cap Inspection Unit can empower your spot welding production line, enabling a dual leap in quality and cost control.